What Exactly is Master Data?

Data retained in SAP R/3 is classified as

- Master Data and

- Transactional Data

The fundamental data that serves as the foundation for any transaction is known as master data. Whatever you're doing, whether you're creating, transferring stock, selling, purchasing, or doing physical inventory, you'll need to keep track of certain master data.

Become a SAP SD Certified professional by learning this HKR SAP SD Training !

Master Data Example

- Material master data

- Customer master data

- Vendor master data

- Pricing/conditions master data

- Warehouse management master data (storage bin master data)

Material master and purchase information records are the ones we'll be focusing on in the MM module.

Material Master: What should you be aware of when it comes to material master?

In SAP, a material is a logical representation of specific products or services that are used in production, sales, purchasing, inventory management, and other processes. For instance, it may be a car, a car part, gasoline, a transportation service, or a consultancy service.

Want to know more about SAP SD,visit here SAP SD Tutorial !

Material master refers to all of the information in SAP about all materials, including their potential uses and qualities. Material master is the most essential master data in SAP (together with customer master data, vendor master data, conditions/pricing master data, and so on), and it has an impact on all material processing. It's why having a precise and well-maintained material master is crucial.

SAP SD Training

- Master Your Craft

- Lifetime LMS & Faculty Access

- 24/7 online expert support

- Real-world & Project Based Learning

You must comprehend material master views and their implications on processes in other modules, business transactions, and a few other pieces of knowledge such as tables that contain material master data and transactions for mass material maintenance in order to be confident in your activities (for modifying the properties of a large number of materials at the same time).

Top 30 frequently asked SAP SD Interview Questions !

Types of Material

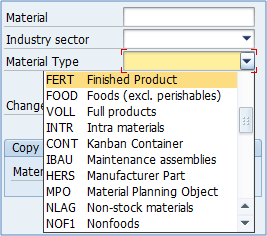

Each material in SAP ERP has a "material type" attribute that is used across the system for numerous purposes.

What does that characteristic signify, and why is it important to distinguish various material types?

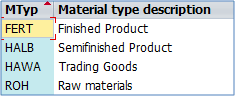

- It can indicate a finished product (completed goods ready for sale), a semi-finished product (used as a component of a finished product), trading goods (for resale), raw materials (used in the manufacture of semi-finished and finished products), and so on. These are just a few of the SAP material kinds available, which include food, beverages, service, and many others.

- If none of the basic material kinds meet our needs, we can create our own.

The most commonly used materials in standard SAP installation

Related Articles SAP SD Sales Document Types !

What could be configured at the level of the material type? (possible discrepancies among types)?

- Material master views: It specifies the views that are connected to a Material Type. For instance, if we have a material type "FERT" allocated to our material Product 1000, we don't want Purchasing based views for that material because we don't need to buy our own product - this is specified at the material type level.

- Default price control: This control could be set to standard or moving average pricing (details below), but it can also be altered in the material master to override the default values.

- Default Item category group: In sales documents, this is used to determine the item category. To override the default parameters, it can be altered in the material master.

- Purchase orders (internal/external), Indicators for specific material types, and a few more.

As a result, material types are allocated to materials with the same basic settings for material master views, pricing control, item category group, and a few other features. The t-code MM01 allows you to assign a Material Type when creating a material.

Related Articles SAP SD Flow !

Subscribe to our YouTube channel to get new updates..!

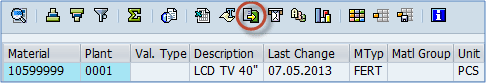

Where can we obtain a comprehensive list of materials, along with their material types?

This can be done in a variety of ways. The raw data is saved in the MARA table.

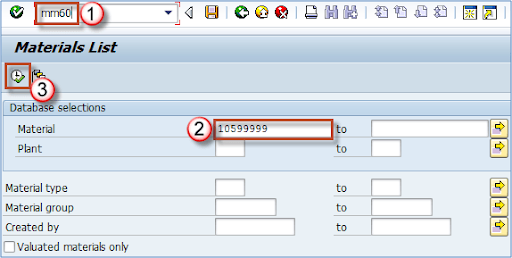

(You can access table contents with t-code SE16 or SE16N – the most recent version of the transaction), however, these t-codes aren't available to normal users in some systems. In such instances, the list can be simply obtained using the t-code MM60 (Material list). The material MM60 is utilized a lot since it has a number of basic material features.

You can only enter the material number at this stage of the selection process:

Material 10410446 in plant AR01 is of type FERT, as can be shown (finished product)

We could export the list of materials we've picked on-screen by pressing the toolbar button highlighted on the screen.

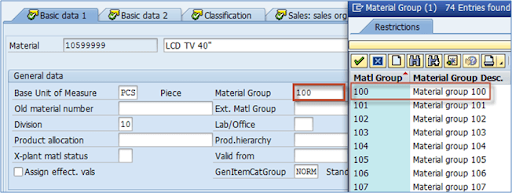

Material group

A "material group," which might represent a group or subgroup of materials depending on particular characteristics, is another feature assigned to SAP materials during their production.

What criteria could be used to create material groups?

Any reporting criteria that suit your needs are appropriate for your system. You may group materials by the raw-materials type used to generate it (Various plastics are employed in the production process), or you can split all services into consulting services (with a variety of materials for financial consulting, IT consulting, SAP consulting, and other types of consulting), transportation services ( international transport, internal transport), you can also group by production technique (Welded materials, extruded materials, injected materials, and so on). Grouping is primarily determined by the method taken by your management, and it is primarily done during deployment, with few adjustments in a productive environment.

Related Articles what is SAP SD !

There's also a material hierarchy (used primarily in sales and distribution) that could be used for grouping, but it's nearly always specified in terms of sales needs because it's used to set sales conditions (special offers, additional discounts, standard discounts for customers).

Material groups, on the other hand, are mostly used in the PP and MM modules.

You could use the previously described t-code MM60 to showcase material groups for numerous materials. All you have to do now is add more materials to your selection criteria.

![]()

Transaction MM17 makes mass maintenance of material groups very simple. In the material master editing part, we'll go through this in further detail.

Related Articles SAP SD Enterprise Structure !

Conclusion:

In this blog, we have understood and learned what is Master Data in SAP and the topics such as material types, configurations at material type-level, purchasing orders, obtaining the comprehensive list of materials, which criteria should be used for creating the material group, etc.

About Author

Kavya works for HKR Trainings institute as a technical writer with diverse experience in many kinds of technology-related content development. She holds a graduate education in the Computer science and Engineering stream. She has cultivated strong technical skills from reading tech blogs and also doing a lot of research related to content. She manages to write great content in many fields like Programming & Frameworks, Enterprise Integration, Web Development, SAP, and Business Process Management (BPM). Connect her on LinkedIn and Twitter.

Upcoming SAP SD Training Online classes

| Batch starts on 4th Mar 2026 |

|

||

| Batch starts on 8th Mar 2026 |

|

||

| Batch starts on 12th Mar 2026 |

|