- Introduction to the SAP EWM

- SAP EWM key features

- Overview of SAP EWM Process Flow

- SAP EWM outbound delivery process flow

- Final note

Introduction to the SAP EWM:

The SAP EWM (extended warehouse management) is one of the functional modules which is used to manage warehouse inventory and supports the processing of goods movements. The SAP EWM also allows organizations to control both inbound and outbound delivery process delivery. and movements in the warehouse. The main purpose to use EWM is to manage the outbound and inbound delivery process, maintain goods receipts, solve goods issues, fulfill customer orders, and goods distributions.

We have the perfect professional SAP EWM Training for you. Enroll now!

SAP EWM key features:

SAP EWM signifies the major key features which are considered so important in any organization; Let us explain one by one;

- With the help of SAP EWM, users can control the various warehouse activities such as picking, posting, managing storage, and good sales document types.

- The SAP EWM helps you to set the alert before the goods receipt transfer from EWM to the SAP ERP system along with this feature, users are also able to perform corrections, reversal, and inbound delivery split from the SAP EWM to the SAP ERP system.

- Users can also perform deconsolidation of the handling of various units that contain product details and their storage locations.

- Users can also determine the storage concepts like product slotting, and optimize the goods arrangements for the warehouse automatically.

- The SAP EWM functional module allows users to perform various tasks like work packaging, and also monitor the warehouse activities which are performed by the warehouse employees.

- The SAP EWM also helps organizations to keep track of the vehicles, and other transportation units (it consists of a yard-in check in and yard-out checkout) activities.

- SAP EWM also comprises storage and handling of various hazardous substances (such as SAP environmental health, and safety EHS).

- SAP EWM allows organizations to store the labor time, and resource usage effectively( managing the resources effectively).

- The SAP EWM cockpit allows users to perform the transportation of products to various warehouse centers.

Overview of SAP EWM Process Flow:

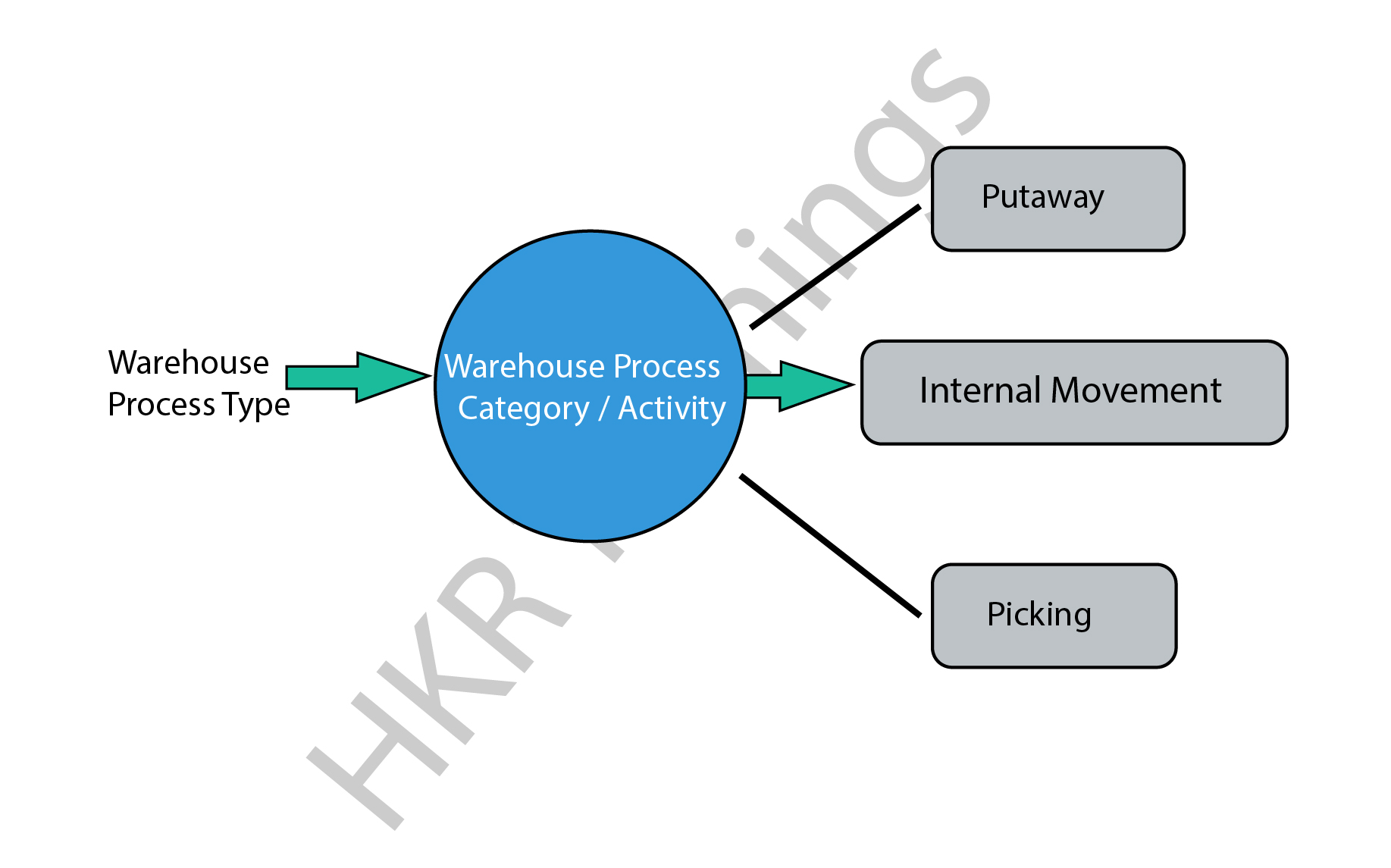

In general, SAP EWM process flow defines the type of activities that have been performed in a warehouse. We can consider the type of activities such as packing, goods receipt, goods issues, and they are assigned to each warehouse document.

All warehouse process flow is further divided into warehouse categories. The warehouse categories also define the goods movement in the organization’s warehouses.

The following diagram explains the process flow of the SAP EWM;

There are various process types also categorized in the SAP EWM system, we would like to mention them as well ;

- Stock removal

- Putaway

- Internal movement

- Goods receipt posting

- Goods issue posting

- Physical inventory

- Crossline putaway

We have the perfect professional SAP Training in chennai for you. Enroll now!

- Master Your Craft

- Lifetime LMS & Faculty Access

- 24/7 online expert support

- Real-world & Project Based Learning

Example 1: Here we are going to explain the internal process type for the picking type as follows;

The steps include are;

- To create a picking type process type, go to the navigation EWM ->click on “cross-process setting” -> select warehouse tasks -> now choose to define warehouse process types.

- You can also select the process type to copy -> then click on the copy at the top.

- To save all the process type details -> then click on the Save button.

Example 2: internal process type for selling and receiving goods:

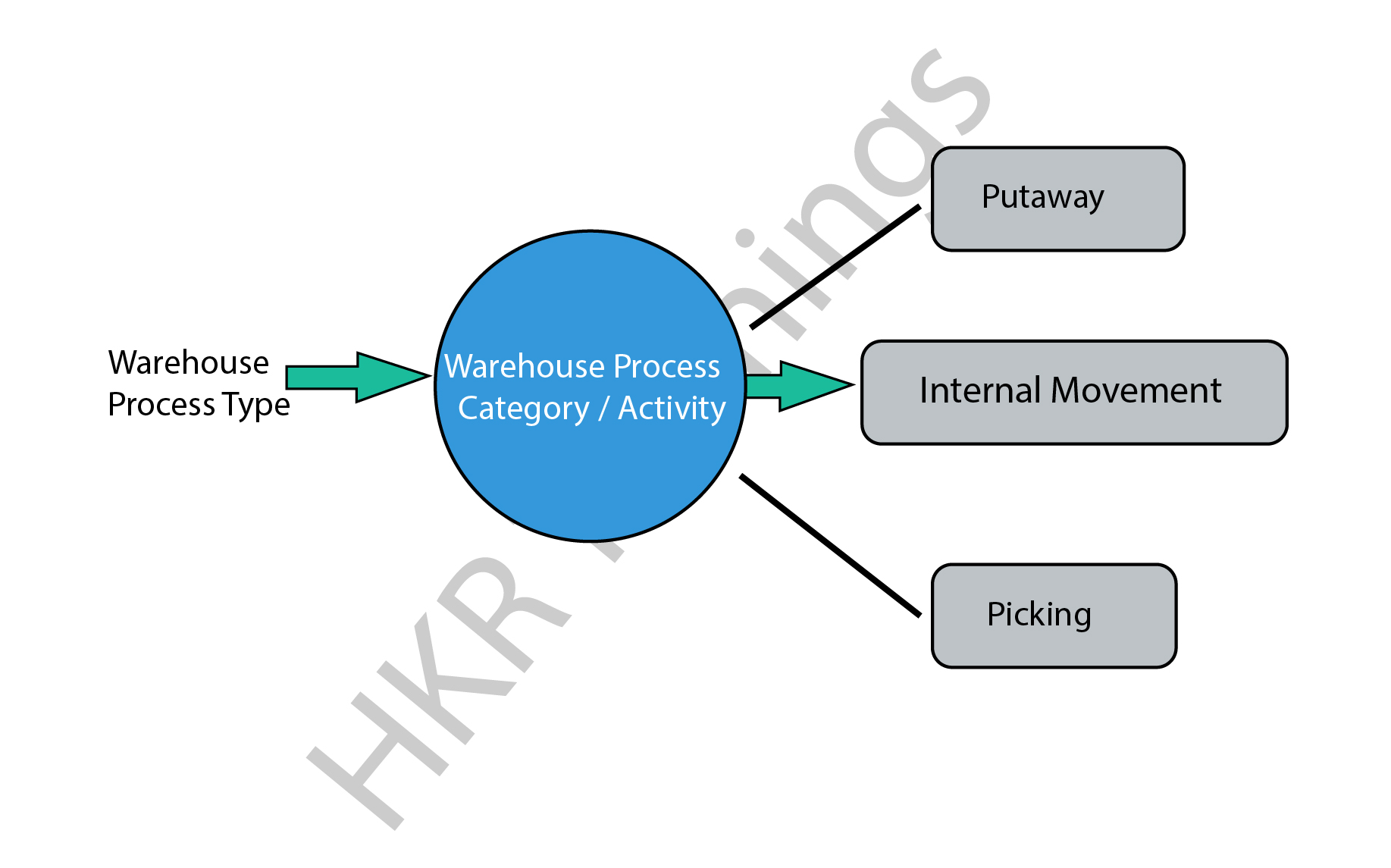

This process involves internal process types for selling and receiving goods/products in the warehouse. In general, the receiving goods process begins in the SAP ERP system once you have detected the purchase requisition and purchase order created. The purchase order composes the quantity of the material stored and plants in the storage location.

There are two ways available to handle the purchase order requests;

- Firstly you need to send the purchase order to the supplier for the goods deliveries, once you receive the goods, the receipt of the goods will keep posted.

- Receive the order announcement from the supplier that is all about the goods arrival and purchase order request.

Note: when you create the purchase order -> you can set the CTRL key to enabling the notification from the supplier. An inbound delivery will be created once you set the control. In a few cases, inbound delivery cannot be created even though you have set the control key.

All the inbound delivery process consists of the following information;

- Goods arrival

- Quantity of goods

- Store details

- Plant location

An inbound process includes;

- Goods receipt and optimization

- Transportation unit inspections

- Quality inspection

- Routing of goods in warehouse

The following image illustrates the inbound delivery process flow,

Points to remember:

- Whenever you make any changes to the inbound delivery, it will affect the SAP system.

- The status of the inbound delivery report can be updated as per goods delivery.

- Successful completion of the goods delivery report will also be updated on the SAP system.

If you want to Explore more about SAP EWM? then read our article - SAP EWM Tutorial

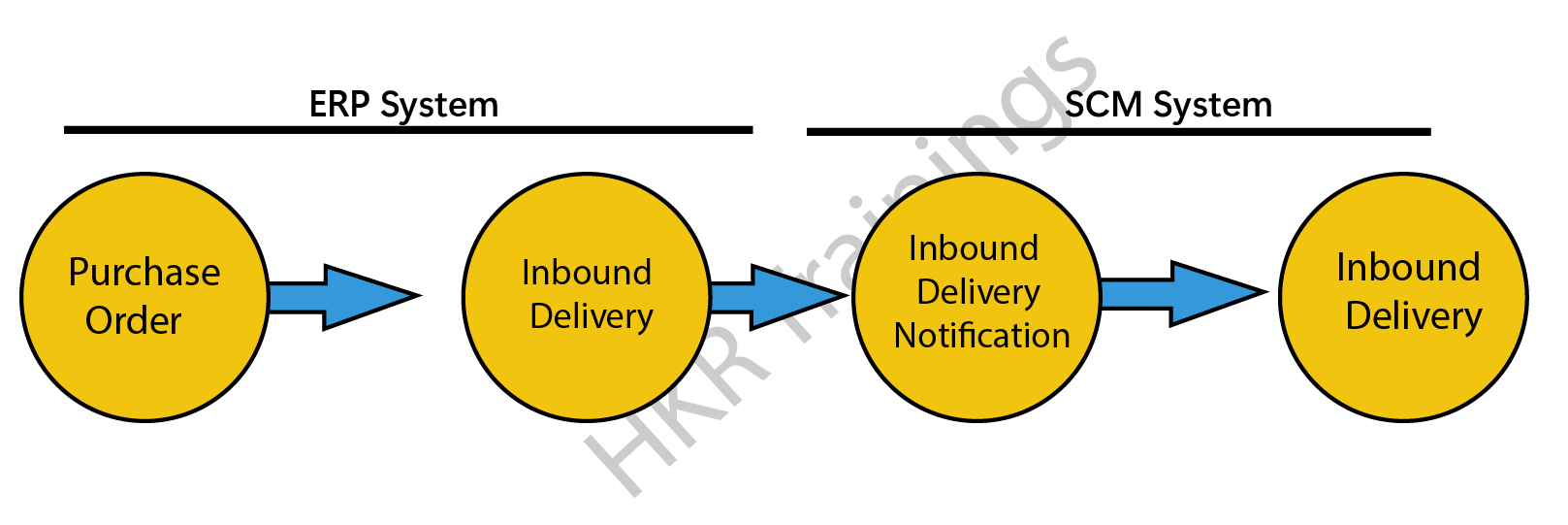

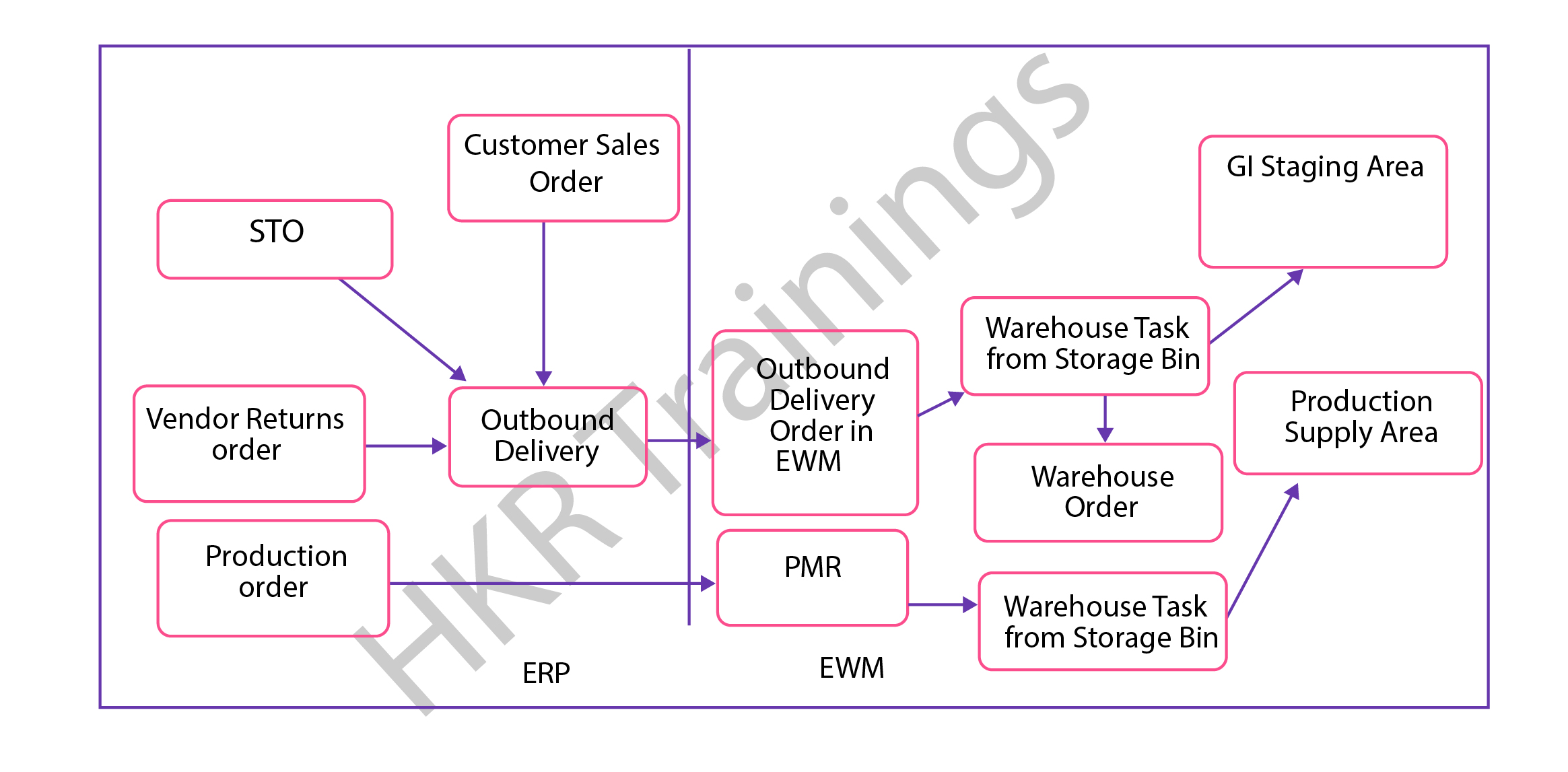

SAP EWM outbound delivery process flow:

The SAP EWM outbound delivery process flow can also be known as the “Picking process”. This process type in the SAP system defines the store bin types in the warehouse. The outbound delivery process also helps to remove the stocks in the outbound goods issue process, this process is often known as the “picking process” in the SAP system.

The below diagrams explain the outbound delivery process in detail;

The types of the outbound delivery process;

- Customer sales order: An outbound delivery process can be created with reference to the sales order to perform various tasks like picking products from a warehouse bin, packing the picked products, and resolving the goods issues which are related to the shipment.

- Stock transport order: this step involves moving the goods within the organization once the supply management issues it and receiving the receipt. The outbound delivery process can be created at the supplying plant, goods packed, shipment, and delivery of the products.

- Vendor returns order: The return order is created within the ERP system if the product delivered failed to meet the customer’s expectations.

Production staging process: in this stage, the appropriate raw materials will be picked from the warehouse bin that is completely based on the order picking strategies and then moved to the production supply area.

The following image explains the types of the outbound delivery processes and overall functionalities;

The important documents created during the outbound delivery process;

- Outbound delivery order: this document popularly known as the warehouse request is the source document that usually initiates the picking activity while creating a specific task.

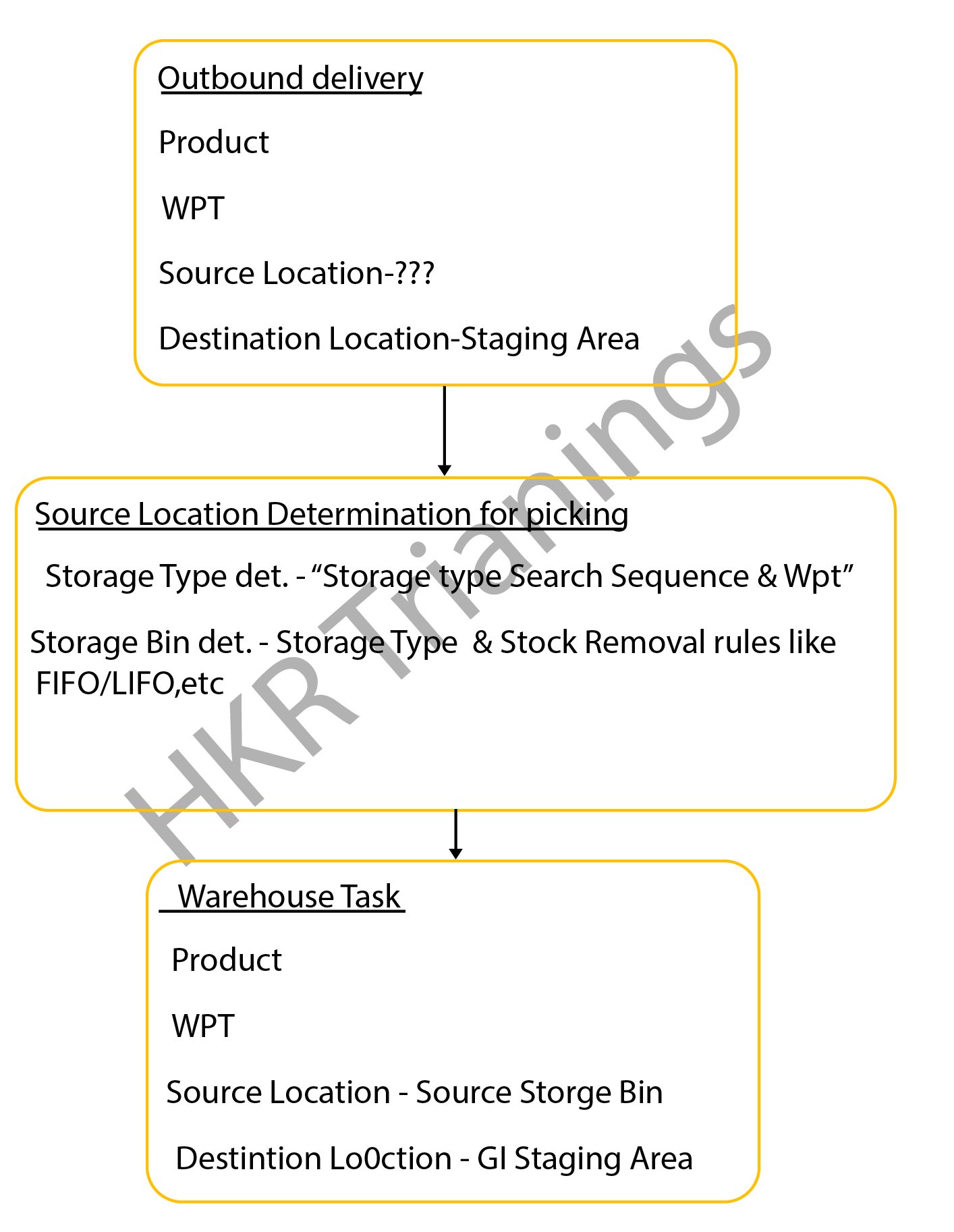

Warehouse task: The warehouse task consists of information like source bin, quality, search, batch, and destination bin. - Warehouse orders: The warehouse orders are also the documents that are assigned to a warehouse employee to execute the product picking tasks at a specific time. The steps included in the storage bin determination in the SAP picking process:The storage bin ty

The steps included in the storage bin determination in the SAP picking process:

- The storage bin type determination in the SAP picking process:The configuration process consists of the following parameters;Warehouse process types, stock removal control indicator (this will be maintained in the master data process), and packing specifications.

- Stock removal determination type in the SAP picking process;This process can be performed based on the system looks available for the storage type or group of the storage types and the storage area where the stocks can be picked.

The overall outbound determination process is shown below,

frequently asked SAP EWM Interview Questions and Answers

Weekday / Weekend Batches

Final note:

The latest survey report suggests that the SAP EWM is emerging as a powerful warehouse inventory management tool. The SAP EWM process flow plays a vital role in delivering efficient outcomes and also managing the storage bin. Our main aim to design this SAP EWM process flow article is to reach a global audience and shape their professional careers. This SAP EWM process flow article helps you to know both the inbound as well as process flow activities and how to perform them in the organizations to maintain the proper inventories.

Related Article:

About Author

Kavya works for HKR Trainings institute as a technical writer with diverse experience in many kinds of technology-related content development. She holds a graduate education in the Computer science and Engineering stream. She has cultivated strong technical skills from reading tech blogs and also doing a lot of research related to content. She manages to write great content in many fields like Programming & Frameworks, Enterprise Integration, Web Development, SAP, and Business Process Management (BPM). Connect her on LinkedIn and Twitter.

Upcoming SAP EWM Training Online classes

| Batch starts on 26th Feb 2026 |

|

||

| Batch starts on 2nd Mar 2026 |

|

||

| Batch starts on 6th Mar 2026 |

|